-

Posts

597 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Downloads

Articles

Gallery

Everything posted by SSIMMONS

-

Also, can you expand the assembly in the property tree so we can see if you are working with all surfaces, solids, etc. Surfaces absolutely nuke a scenes performance.

-

I would be happy to make some clips for you if you ever have specific questions or maybe think there may be an easier way of doing something, but need to know how. -Spencer

-

If you want to be really fancy you can bind it to a new shortcut or mouse button, but I don't even do this. I do the right click in scene browser method mentioned above.

-

Yeah, this .ifc import was something we were pushing for several years ago and they got it done pretty fast. We have several clients that have MASSIVE files and .ifc files were a nice mix of functional and smaller sized. Mostly we use them for importing structures and doing machine layouts etc.

-

What kind of hardware are you using?

-

Nice find!

-

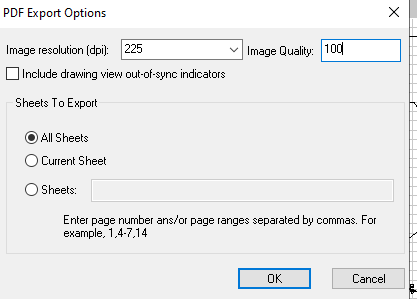

Maybe your source logo is far too large and IC in massively compressing it or something? We have a logo and it looks fine when we export, pretty sure it is just a JPG.

-

Convertio will also do this.

-

I am cross-dominant. For instance, my highest bowling score is 200 points and it is shared by my right and left hands. I cannot snowboard with my right foot back like most right handed people, only goofy stance. I play pool left handed and am horrible right handed. I can throw a frisbee well with either hand. I write right handed and throw a baseball right handed, but I can throw left. It just depends on the task. I do pick things up much faster no matter what it is, but some things I am just terrible at with one hand or the other. I am a right handed shooter with left eye dominance (which is a bit weird at times). It's just all over the place really.

-

To be fair, IC works primarily on intellishape features and I generally would not add features like holes etc. in a sketch because if the intellishape bounding box is edited it would mess up the shape and size of those features. I always find it interesting what bothers some people and not others when it comes to this sort of thing. Couldn't hurt to make it easier though, but I would likely never use the feature since I just right click and hit edit sketch and whittling this down from 2 seconds to 1.75 seconds isn't a huge gain in productivity. Is there not currently a way to bind this to a mouse using the customize keyboard shortcut menus (Like select the part and click one button and it automatically brings up that parts cross-section edit)? That might be pretty neat if there isn't.

-

I use the steel catalog and build reliefs and bolt pattern manually from standard ASCE profiles. It sounds slow, but I knock out an entire structure in a day sometimes (the geometry, not the analysis). Then usually the next day I will rebuild in a software called RAM elements by a company called Bentley and run all my codes and Civil Engineering loads etc. to make sure it passes all modern (ASCE 7-16 in ASD, not LFRD because I make large support structures for bays of machinery mostly and not sky scrapers etc.) codes based on geographic location (historical winds, snow if applicable, historical earthquake data, etc.) and I can honestly say I have zero complaints about the speed or anything. I am a Mechanical Engineer so I know those of you that actually took Civil Engineering should find it easy after a bit of practice. Side Note: if you are doing the design AND civil parts use this website, it is a real time saver. I used to use textbook maps until I eventually double checked a million times and they always matched. https://ascehazardtool.org/ -Spencer

-

-

Ah, thanks Kevin. I knew there was a way, but couldn't remember.

-

Is there a way to make default behavior when dropping an IC fastener to NOT display thread callouts in ICD. Some of my co-workers computers are fairly old and we have hundreds of fasteners typically so this slows down peoples ICD loading significantly. Thanks. -Spencer

-

This is correct behavior. I work with two others and we work on the same things all externally linked. You just have to alter your workflow to accommodate and it's a non-issue. Work on subassemblies in parallel and you will have no issues so far as no one opens the main project (which why would they if they are working only a sub-assembly) and they do not share a common part (lifting lug present in both sub-assemblies etc.). If they do share a common part, allocate those sub-assemblies to the same person and problem solved. It's not frustrating if you just coordinate with the people working with you. This also allows for everyone to be more in-tune with other aspects of the project because a certain amount of information of each sub-assembly must be understood. -Spencer

-

Powerful feature, very much looking forward to using it. Thanks for sharing.

-

I think this may have been a carryover from the CVP (beta version). I seem to remember something about the drag drop step import not working, but you could manually import using the button on the toolbar. -Spencer

-

Advise on how to add triangular gusset to a pipe?

SSIMMONS replied to Aleman15's topic in General Discussion

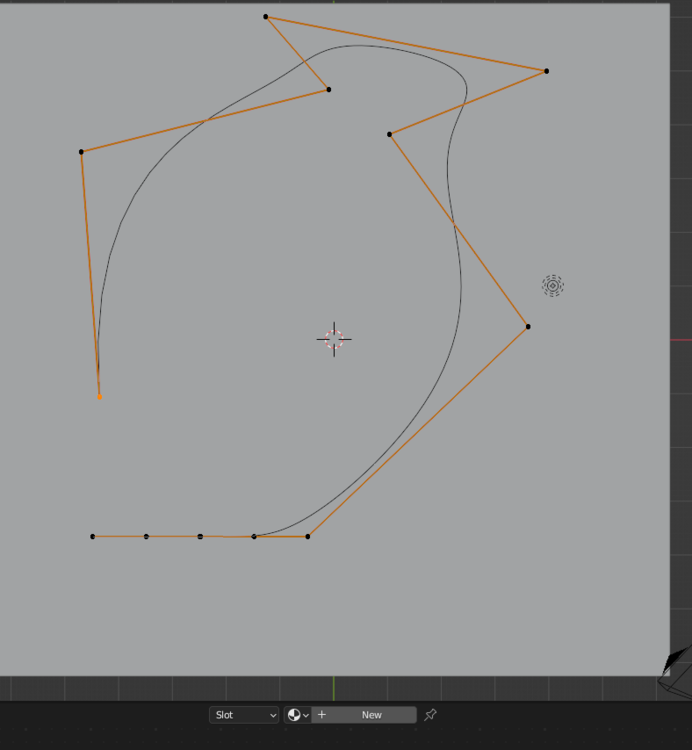

Can you clarify what you mean by this? Simple sketch would help. -

I am not sure exactly what you are asking, but IC MECH has a utility called "PRO Active Manager" that might be what you are looking for. Or if you are simply asking if you have multiple of the same part can you add that custom property to all those same parts at once, the answer is yes by using the custom properties and ensuring the parts are linked within the scene.

-

Yes, it is a new version of the software so it is like buying a new software. New key needs to be purchased.

-

Season's Greetings to the Team and the Community

SSIMMONS replied to jolizon590016's topic in General Discussion

Cheers Everyone! -

Keep in mind that a welder and a grinder are magical things. Even with little corner gaps (the bend corners will just naturally create gape when bending) you can fill them roughly up to the thickness of the material and grind the visible bits flush to look really nice. This is from a more practical perspective, but if you want it to just look good on the screen and let a fabricator make it work then the method above looks really nice to me.

-

Example file?