-

Posts

55 -

Joined

-

Last visited

Previous Fields

-

Computer Brand/Model

HP Zbook 15 x360 G5

-

Processor type and speed

Intel Xeon E-2186M @2.90Ghz

-

Amount of RAM

32GB

-

IronCAD Version/Build #

Latest

-

Graphics card

Nvidia Quadro P1000M

-

Operating System/version

Windows 10

Profile Information

-

Location

Australia / New Zealand

Josh's Achievements

Cylinder (3/9)

7

Reputation

-

Josh started following Request: Thread Tool - Suggested Enhancements , Ironcad On Mac! , Having to re-set sheet metal orientation handle every time and 6 others

-

Hello! Just installed on an Apple silicon M3 Macbook with Parallels + Windows 11 and... it works! Had to change graphics driver to OpenGL2 instead of DirectX, but nothing else was needed. (Menu>Options>Rendering>Driver Type) Note: I only just tested this, threw in a few parts to see if it could handle them and all worked fine. But I haven't done sustained work where I assume there might be problems floating around different areas.

-

Having to re-set sheet metal orientation handle every time

Josh replied to HDEAR's topic in General Discussion

Good question! No idea whether curved stock takes into account Kfactor, I assume it does not and assumes the curve is going to light enough to disregard Kfactor. -

Having to re-set sheet metal orientation handle every time

Josh replied to HDEAR's topic in General Discussion

If it's a bend (not stock with cross section), then you can make a parameter that controls the length and apply it by filling in the length field in intellishape properties. If it's stock (with cross section), you can apply the parameter with a 2D sketch SmartDimension. 2021-05-03 13-15-33.mp4 -

Having to re-set sheet metal orientation handle every time

Josh replied to HDEAR's topic in General Discussion

I'm not 100%, but I don't think this can be stored as a default, it's meant to be a one-off change to solve complex sizing needs in the moment. I would say: a) Size in the other direction the second time b) If this is something that changes really (really) often, make it parametric and do the angle/length calculation with a formula. -

Makes sense, pretty sure that should be a K factor of 1 then if there's no elongation.

-

Hi Joseph, I think the lost material in the real world prototype might be caused by the k-factor. Made you a video below: 2021-05-02 15-45-03.mp4

-

Are the icons in the ribbon bar available somewhere?

Josh replied to Lykle's topic in General Discussion

Nice! I do love a productivity hack. You could try delve into the Gestures side of IronCAD as well, I haven't done that in a while. -

Are the icons in the ribbon bar available somewhere?

Josh replied to Lykle's topic in General Discussion

@Lykle I have them separated out of the string into individual files for each command (was needed when building the Academy). If you only need a few, then what the guys mentioned above is easy. If you need a big batch of them, just send me a message and I can send them through. -

I know someone who was using a Surface Laptop (no GPU) and it seemed to run well. You don't need Windows "Pro" versions, I have used IC many times on non-pro windows versions like home-edition etc. Touch will not work very well, at the moment it is near-impossible to use IronCAD without a separate individual mouse. Touchpad and/or touchscreen both don't really have support. I have tried in multiple different ways to use IronCAD with touch screens by customizing things, it's possible, but painful. So it will probably run fine on Surface Tablet, but it will still need a mouse plugged in so not much use from the "tablet" side. And the GPU (or lack thereof) will probably struggle with any really big models. I would really like to see touch support and pen/stylus support for IronCAD. Small laptops, tablets, and even phones (!) are now powerful enough to run CAD software, so I think the future of design software will involve a lot more mobility and designing with portable devices. E.g. carrying a tablet or foldable smartphone onto a worksite or into a factory, and being able to design efficiently in the palm of your hand rather than needing to travel back to a desk with an external mouse.

-

Drawing perf metal without bringing the system to its knees

Josh replied to HDEAR's topic in General Discussion

@HDEAR Nice! Great to hear it worked. Must've been a tiring day for your computer's fan! -

Drawing perf metal without bringing the system to its knees

Josh replied to HDEAR's topic in General Discussion

Small feature patterns like these are often painful, it would be lovely if patterning was multi-processor... Not sure about ICD or CAXA, but have you tried doing this with the new "Fill Pattern" command? It will still be processor intensive, but once you have it set up it should only require one size change and the holes will all automatically update for you rather than needing to manually copy anything. You could suppress the pattern when you don't need it to avoid big regen times. Here's an example if you haven't tried Fill yet: 2021-04-08 15-23-28.mp4 -

3D printers - advice please on what to get for starters

Josh replied to HDEAR's topic in General Discussion

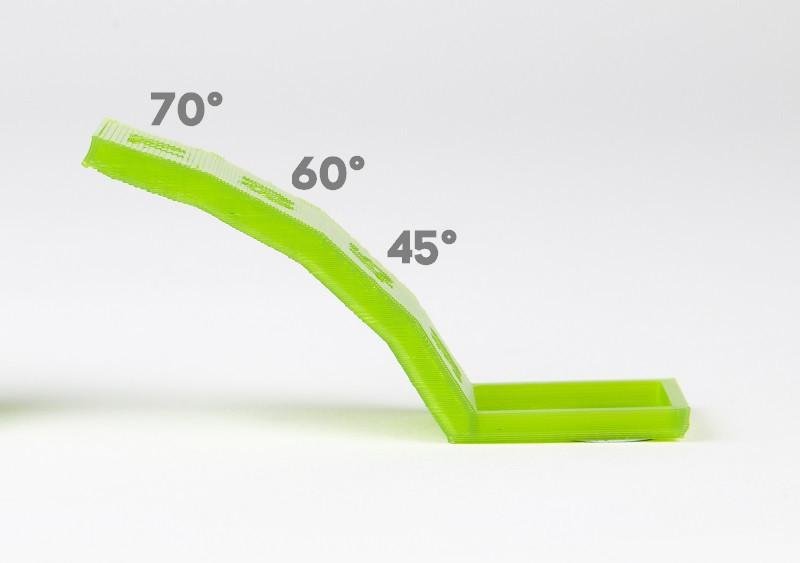

Haha great point Jan! Definitely good to be ready for lots of tweaking, especially with more difficult materials. I would add that while there are various important limitations to learn when designing for 3D printing with FDM, there are also some capabilities which surprised me and are not intuitive. Things like bridging and printing at large overhang angles. Learning how to apply these can make for some really fun design work! Overhang and bridging examples below. Very fun. @jvik I've always just increased my STL resolution stupidly high, that's great to know if the slicers work with OBJs. BridgeVideo.mp4 -

3D printers - advice please on what to get for starters

Josh replied to HDEAR's topic in General Discussion

@HDEAR I have a Prusa Mk3, it's great. It's been really reliable, and can easily be tweaked in lots of ways. If it ever does break there will likely be plenty of spare parts and a community of people that can help fix it (the Prusa community is big). Depending on how much you like building Ikea furniture, I would recommend getting the pre-assembled version rather than the kit. Assembling the kit is easy, but VERY time consuming. Expect at least 6 hours of little screws and reading through instructions if you buy the kit. Mine literally sat unused for many months because I was busy and didn't get around to it, because I knew it would take so long. Eventually I got around to it and it's been a ton of fun. I haven't done the multi-material kit yet, as I've read it can be extremely finicky, and I haven't needed to do much multi-material stuff (you can still do multi-material without the kit, you just have to change the filament manually which is easy as long as it's only a few changes per print. IC works no problem, you just export your file as an STL (Stereolithography) and then import into the Prusa software which creates the Gcode for the printer. Note when exporting STLs, increase the resolution to around 200 or so, instead of the default "fine" or "course" modes, because both those modes are pretty course in reality. (This should be fixed in a future IC update I hope). Filament Don't worry about buying lots of filament, once you start printing you will probably realise the filament you want is different to what you bought and so on. I have a ton of filament I bought at the beginning which is probably never going to be used. There are some cool companies making recycled filament if you want to use that too, filamentive.com are great, and I've even got some Nylon filament made from disgarded fishing nets. From an environmental standpoint, from what I understand recycling PETG (made from oil) is likely better than using new PLA (made from plants) which is theoretically bio-degradable. But defintely get some PLA to start, as it's a little easier to print with than PETG. Although note PLA can't be used for many real world applications, even if you leave it in a hot car in the sun, it will ruin the print (it has a very low melting point). Carbon fibre filaments are very overated. I wouldn't bother with them (I have some). Basically they are more stiff but weaker than standard. This is a good resource for materials: https://help.prusa3d.com/en/materials Other stuff This guy (CNC Kitchen) has a great YouTube channel with a ton of info on filament, material strength tests, printer tweaks etc. https://www.youtube.com/channel/UCiczXOhGpvoQGhOL16EZiTg I have some cool models that I can send you that I have printed. Including a replica of the NASA 3D printable fabric made in IC. It's a good idea to buy some spare nozzles, you can clean nozzles, but when one gets clogged it's a pain and much better if you can quickly swap a new one in and clean the other one later. This is a great video to get you excited about possibilities. Have fun! -

Request: Units of Volume Based on Density Units (not Length)

Josh replied to Malcolm Crowe's topic in General Discussion

I agree, should default to Density units. -

Request: Thread Tool - Suggested Enhancements

Josh replied to Malcolm Crowe's topic in General Discussion

I agree parameters in the thread tool would be a great improvement and I know this limitation got in the way of a customer's project recently. I'll add a 6th one: We should really have pre-made threads, instead of requiring drawing a cross section every single time. It should be possible to choose from a list of pre-sized threads, and then only customize if actually needed. This would also allow the user to save their own threads to the list. At the moment, it's like someone wants to buy new tires for their car, and instead of showing them 50 tires to choose from, we just provide some rubber pellets and say make your own tires from scratch. We should have a list of threads that work automatically, and then the ability to customize their values where required.