-

Posts

8,555 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Downloads

Articles

Gallery

Everything posted by tlehnhaeuser

-

How to pull out my sketch from an extrude?

tlehnhaeuser replied to Afwe Rew's topic in General Discussion

Another way to do this is... Edit Cross-Section > Select the desired geometry > Right click on the geometry and choose Create > Extrude, then CANCEL. This makes a new 2D Shape of your geometry you can use or store into a catalog as well. -

What’s New – IronCAD 2021 Product Update 1

tlehnhaeuser commented on Cary OConnor's blog entry in IronCAD Corporate Website Blog

ok thanks -

What’s New – IronCAD 2021 Product Update 1

tlehnhaeuser commented on Cary OConnor's blog entry in IronCAD Corporate Website Blog

will the integration be may available for the newer Rhino releases? -

What’s New – IronCAD 2021 Product Update 1

tlehnhaeuser commented on Cary OConnor's blog entry in IronCAD Corporate Website Blog

Is the Rhino integration still apply or just able to read files now? -

-

LOL! Well Harley its always as long as you need it.

-

You know, once in awhile if you stop working, take a shower, go to bed, wake up and get a cup of coffee, all the worlds answers appear to you. So I now know the practical use for this. Ignore my question.

-

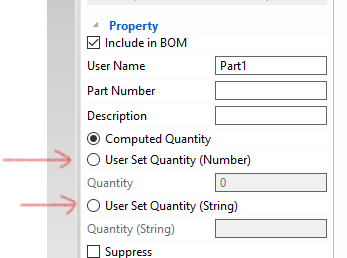

Thanks Cary, I dont fully understand the string - What would be a practical purpose for this? Tx Tom

-

I tried to fins in help but couldn;t find. Could someone tell me the differences are between the manual overiddes "Number" and "String"? Tx Tom

-

i reached out to them and they said they dont ship to USA but they are looking to maybe in the future

-

OH Man!!!!! Harley, I got to find out how I can get some of that!!! tx t

-

How to direct face edit but keep the ability to change sizes

tlehnhaeuser replied to bmckelvie's topic in General Discussion

Just one more for the road...You can always create your own "end cuts" as Intellishapes and save them to a catalog. If you add Design variations and SmartAssembly attachment points it could also be very powerful. I don;t have an example, but if I find time, I may make a video of this. t -

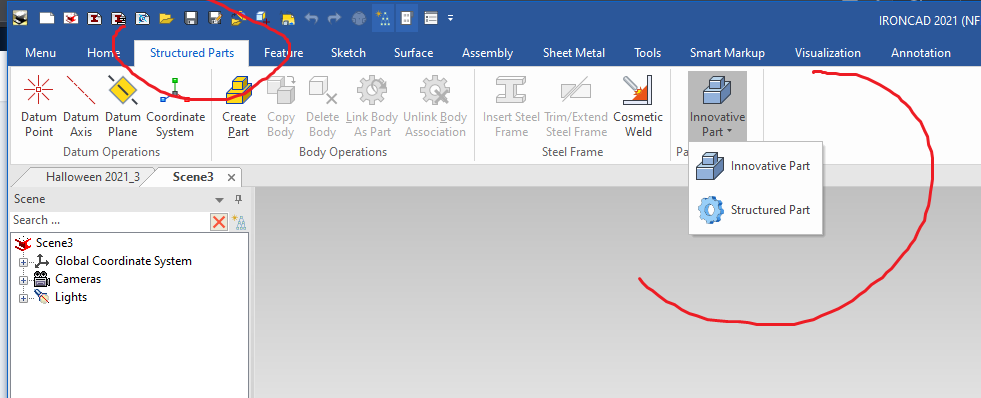

Structured part design toggle missing from status bar

tlehnhaeuser replied to bmckelvie's topic in General Discussion

This was moved to its own ribbon bar tab. Its not on by default so you need to customize the ribbon bar to add it. T -

3D printers - advice please on what to get for starters

tlehnhaeuser replied to HDEAR's topic in General Discussion

sweet! I'm still eating cheeseburgers and now my shape would be better if I learned to walk on my hands. -

3D printers - advice please on what to get for starters

tlehnhaeuser replied to HDEAR's topic in General Discussion

Hi Harley, Your son did a nice job! Some artifacts but mainly on the PLA but all in all its surprisingly not bad at all. Take you son out for a cheeseburger!!! -

3D printers - advice please on what to get for starters

tlehnhaeuser replied to HDEAR's topic in General Discussion

Hi Harley, Not sure if you know but I resell 3D printers and always looking to new ones to test and represent. That being heres my input. First, ultimately, what do you want to do with your 3D printer? That is the major question because the answer will take you into several worlds where you can get lost :-) Do you want to print Plastic, Metal, Nylon, Carbon Fiber, Resin Do you want to print strong functional parts for automotive, household, shop etc... Do you want to create art? Do you want to create very detailed art? All these will steer you into different types of 3d printing. That being said, lets assume you want to print general use "plastic" type prototypes since you mentioned the PRUSA. Although I have never tested a PRUSA, the reviews seem to indicate its a good machine. I have tested Formlabs - forget them, its more trouble than its worth. I've tested Makerbot, forget them too well overrated and many issues. Many I have tested already no longer in existence ie Type A machines. I have and represent 2 brands which I like for various reasons - ZYYX and Raise3D. The easiest 3D printer I have ever used is the ZYYX plus, it doesn;t have all the "overhead" others have and no heated bed which makes printing a dream. Somehow they figured out how to print great without it. However, its still relatively "new" company and based in Sweden, so support is a little lagged if needed. The Raise3D products are great, all of them. The machines built using construction grade metal materials and no parts using the the construction are 3d printed like you will find in most other products. It makes for a reliable machine, the E2 model allows you to print 2 parts simultaneously which is great if your want mass production. IRONCAD works just fine as Josh noted, the only thing is I tend to use OBJ files over STL files, they just seem to me to be a little cleaner. Any other questions, just holler. Tom -

Spencer nailed it. If you require very detailed 2D documentation and more advanced 2D type functionality, then I recommend CAXA. If you have somewhat detailed 2D documentation requirements and want ease of use, then ICD is better. I too would prefer development in ICD over CAXA, It looks and feels more connected to the 3D and other mainstream applications. My2cents Tom

-

training IronCAD Academy Feedback/Suggestions

tlehnhaeuser replied to Josh's topic in General Discussion

Josh, I think a great addition would be the "Commands" toolbar for the ICD Environment. Cheers Tom -

Attachment Points on IntelliShapes?

tlehnhaeuser replied to tlehnhaeuser's topic in General Discussion

Hi Guys, Thanks for the feedback, its always appreciated. Cary, if I pick another edge, no on them seem to work, hmmm Malcolm, this is truly a work of art, you are the structured part guru, the only problem is I am trying to develop for a customers that do not use SPM ever and are casual users, so this is a little over their heads. However, it makes me think how in depth SPM can be, I never realized all those little "tools" within them that I will need to really dive into. I'm just curious how many companies use SPM over IPM. Again thanks both, much food for thought Tom -

If anyone knows a trick to attach and attachement point to the corner of an Intellishape, please share :-) Tx Tom

-

Not sure RJ, but you can look into Active Presenter. btw, theres a free version to test out

-

You guys inspired me to update my video and make it better. Enjoy Tom

-

Thanks Malcolm, very helpful. I've been using IronCAD so long that the notion of "bodies" is still foreign to me and will require much more effort for me to understand. My brain cells are not what they used to be :-) I am assuming this is how all the other mainstream CAD applications have to do this since "Structured" mode basically mimics the same approach? T

-

Hi Malcom Great video, quick question. How would you have ONLY the second body (block) linked? In other words, I do not want the hole and blend to affect the second part? TX Tom