Search the Community

Showing results for tags 'sheet metal'.

-

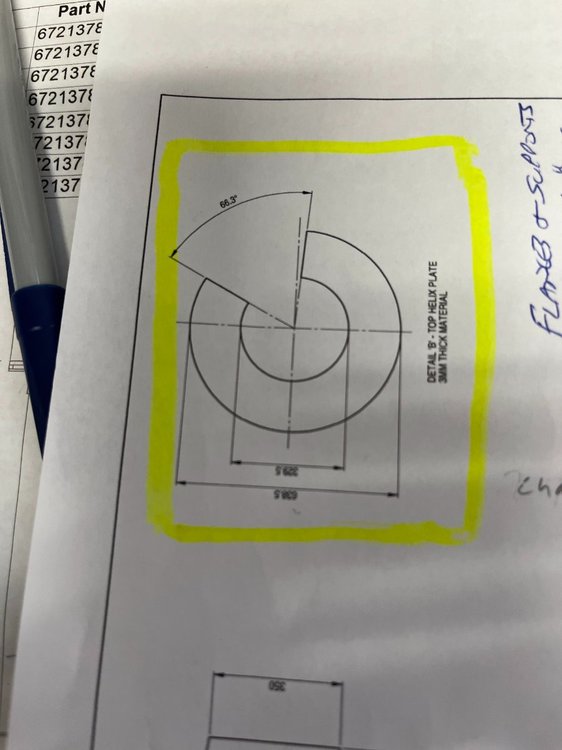

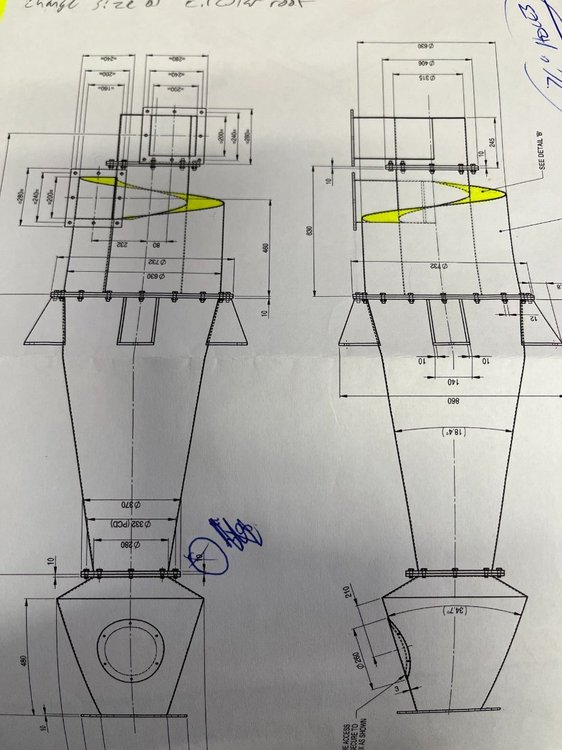

I need some help with a modeling issue. I'm trying to make a helix plate for a cyclone. I need it made out of sheet metal to make a flat pattern of it, but there isn't an option to sweep with sheet metal unless it's like a duct and not a plate. I attached some images showing what the helix plate and the flat pattern (highlighted) should look like. Any help is appreciated.

- 2 replies

-

- helix

- sheet metal unfolding

-

(and 2 more)

Tagged with:

-

Hi all, I'm in a bind. I have a project we're doing in Australia and was getting about 180 odd panels made in NZ and shipping over. Due to the shipping shemozzle caused by the Wuhan Flu pandemic, I now have to get the panels made in Australia. The problem is there are 19 different panel sizes/shapes and I need to change all these panels in my model for 2.00mm Galv with a K Factor of 0.33 and inside radius of 2.00mm to a K Factor of 0.5 and inside radius of 2.95mm. That's over a day and a half's work to manually change everything and resize all the different panels, most of which have at least 6 folds, not to mention heaps of holes ( lucky I used cut cylinder instead of Round s/m profile ) So all you clever people, is there a short cut, or trick or special tool I can use so that I don't have to resize all these panels yet change the K factor and inside radius to what the Ozzies require? Thanks, Harley

- 5 replies

-

- sheet metal

- changing k factor

-

(and 1 more)

Tagged with:

-

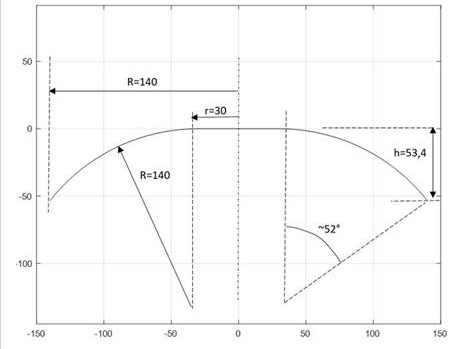

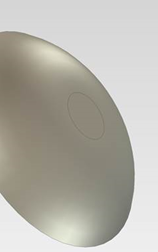

Hi, Does anyone know or have a smart idea to create a spherical shaped sheet metal? If this is even possible. The shape should look something like this:

-

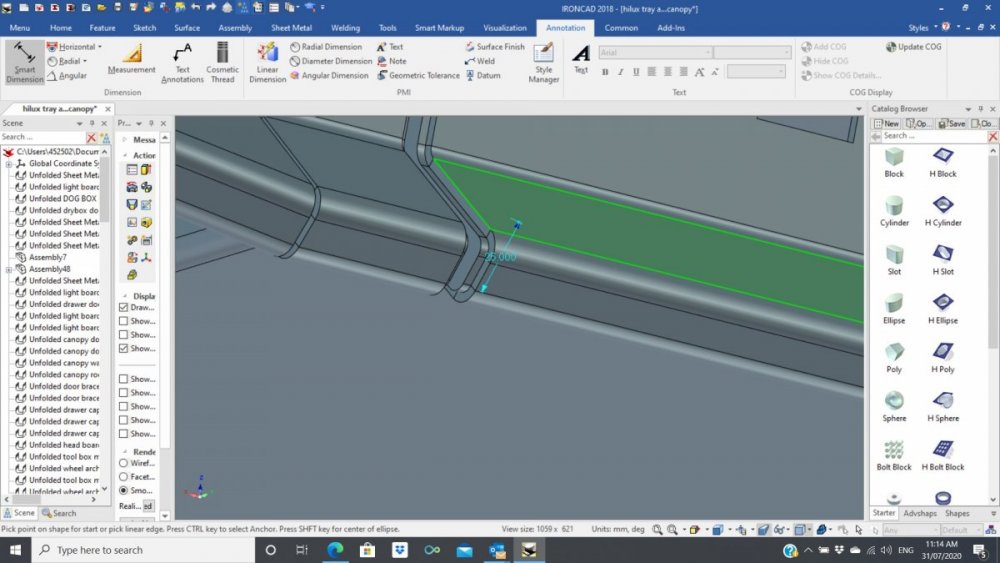

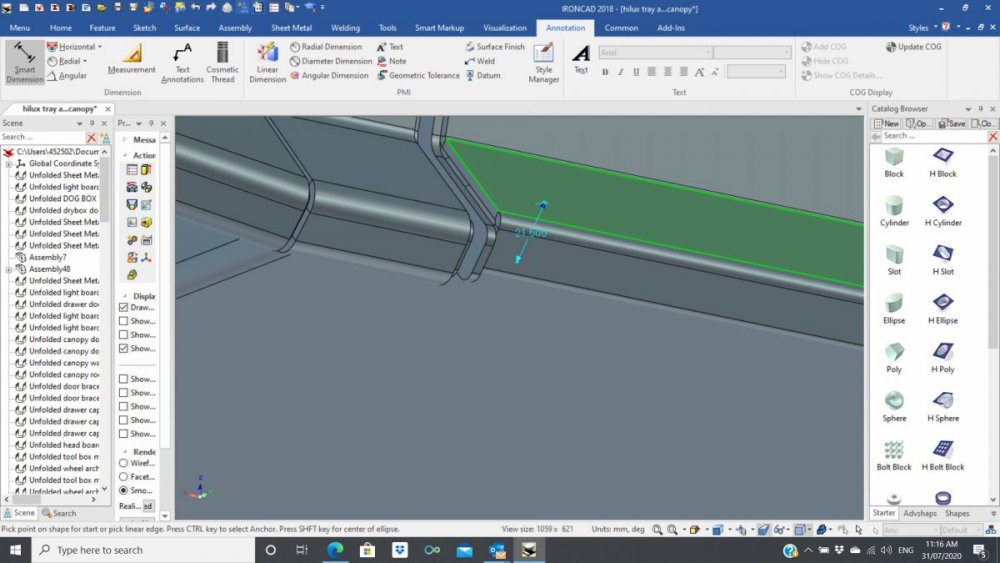

Hello! I am trying to create a sheet metal box with angled bottom. It is 2 L shaped pieces that will be welded at the corners. Im having a problem getting miters on the flanges on the bottom. Not sure if IronCAD can handle it since its angled. Ill try to attach the file so you can see what I am talking about. Also the corner conditions seem off as well but im not sure. as well there is this video of someone making essentially the same thing in solidworks: Thanks! Angled Bottom Box Test.ics

-

Hi , just wondering if anyone could help me out with this . We have changed manufacturers and they have different v blocks for there presses which have a tighter radius , so I am having to change all of our sheet metal parts from a radius of 4.5mm and a k – factor of 0.44 to a radius of 1mm and a k-factor of 0.2 . The problem i am having is that when I change the radius of the bend the over all size of the part is completely changing , I think its because the parts were drawn with the bend feature not outside bend feature so i am losing the difference in radius on the parts , is there any way around this with out remodeling with the new part properties ?

EmilRindell.thumb.jpg.29678b5c5d1acabccc15c66d12b57b42.jpg)