ASPEER

-

Posts

53 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Downloads

Articles

Gallery

Posts posted by ASPEER

-

-

I can see that your sizebox has become offset from the actual shape, I certainly encountered that a lot when I was setting up my smart model, but the only way I remember fixing it was to literally backtrack to before whatever change caused it. There may well be better ways but I didnt find them.

Your parameters look a bit odd to me, but that might be my inexperience. All your equations are integer based, which iirc round down, so the section of missing components looks like a working as written scenario to me. You should add a remainder fill section to your parameters and model, typically I would make this section always there and with range of [0,1) unit (if I read correctly 96" in this case), unless you want to have the model move in steps.

-

I strongly suspect I did something similar when I made a few of my smart models, however, fortunately for me the orientation doesnt matter. I think you may be able to fix this issue if you delve back into the construction of your smart models and re-orientate your sizebox part so it aligns with how you want your model to work (or the other way around depending on what is easier). Another option would be to change what your parameters are pointing to.

Now I think on it does your model expand in a different direction to what the handles drag the sizebox to?

-

Is this the video you were after?

-

-

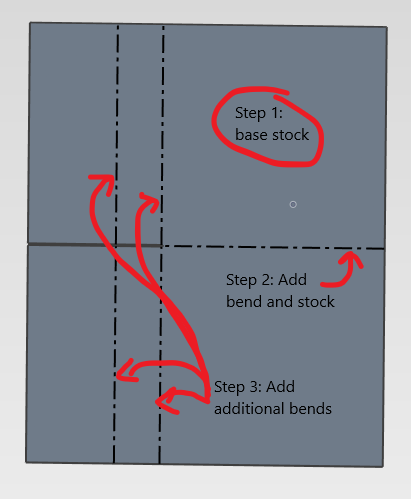

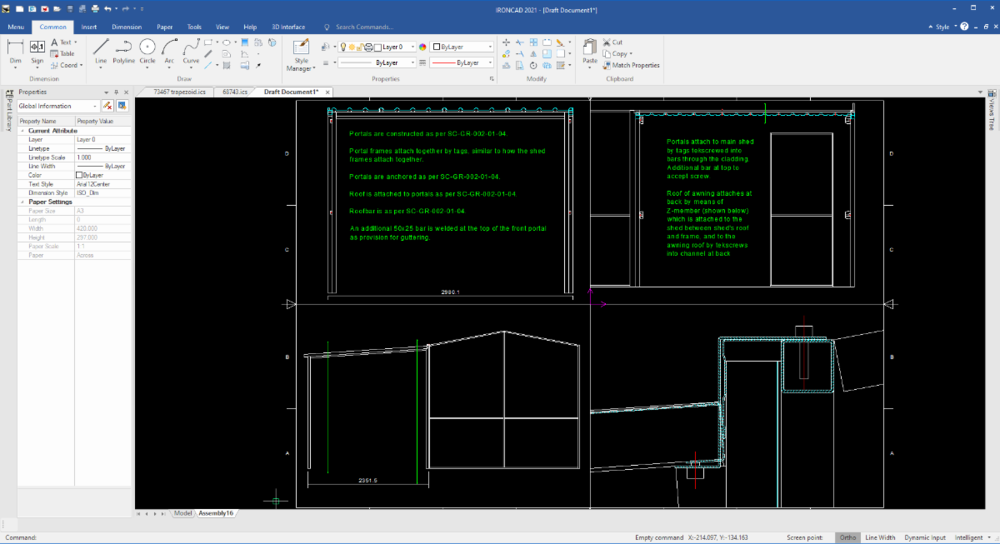

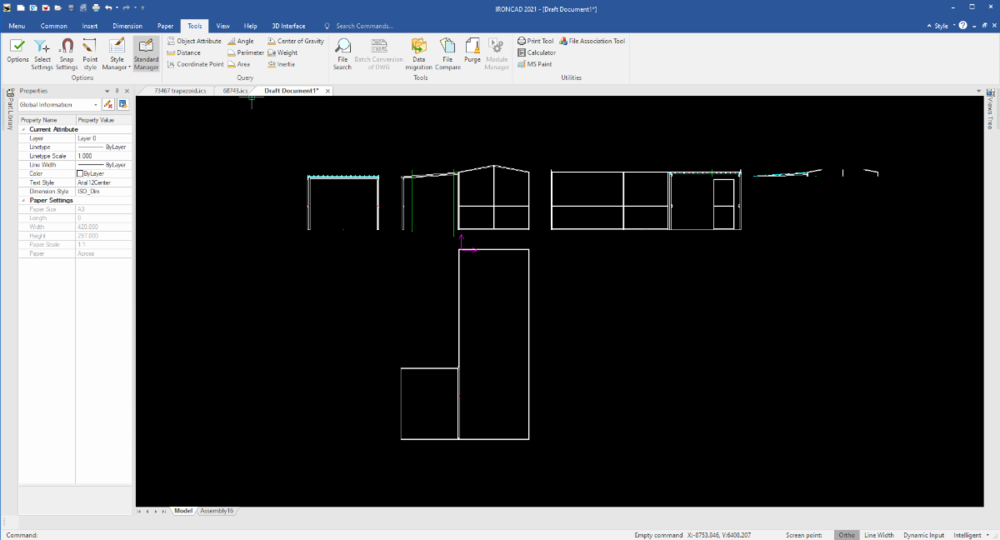

Aleman, for the first one you are attempting to make, if I understand you correctly, you want to have a cut along the horizontal bend line to separate the top and bottom halves of the vertical bends. It is my understanding that this will work just fine if you model it like you would make it, ie cut the notch before you bend it horizontally. If you want to model to work out what the notch should look like, you can not model a V at first, just a break between the different sides of the bend and remove the overlapping material later.

I attached a couple images of what I recreated from your post. I made it from bend and stock parts, base stock in top right and then built out from there.

Andrew

-

I am curious why you would use an air tool as a base for an electric tool, personally. Unless Lee meant air drill (the base looks like a screwdriver or impact driver).

The way I would tackle the problem would be aalbe's method, but that is due to simplicity.

-

I use a crude RHS intellishape made from a shelled extrude with rounded edges. SHS is a rather simple shape so if you only need to have a representation with written in details it should be quick and easy.

-

Very nice Kim. Coincidentally I was looking at doing something similar myself, and in my research I came across a couple of technical details. The worm gear wheel needs to have a bit of space around the worm for the lube, this is usually done by either using a slightly larger cutter, or making a couple passes slightly offset from each other. The other concerns the worm, in that they often control the backlash in worm gears by having slightly different pitches on either side of the worm's tooth (teeth).

I also note having more turns in your sweep cut would change the tooth profile slightly, towards a more involute profile.

-

Kim, it looks like the issue is with the units. Test23 has units of mm2 but it looks like the conversion from default units (m) to mm only accounted for linear units (m => mm) rather than area units (m2 => mm2). Test24 is unitless and has been converted to mm.

-

This looks like a Two Points blend use case to me.

-

The way I typically would do something like this is use the triball link the identical members to position. Typically the most difficult part to this is getting the distance between each right, however given you have the sketch, that info is readily available to you.

The specific steps I would take:

- Take the brace and mirror it to the reverse position (rotate works too)

- Select the second, and translate both of the braces to fill the pattern

- Delete the excess brace

Now the braces are linked.

-

Most of those braces look identical just orientated differently, if they were linked rather than copied/new instances, the property info would update automatically as Ironcad considers them multiple instances of the same item.

-

Another cause may be that the assembly is offset from the sizebox, unfortunately in my experience this requires a larger fix than the methods Kim put forward, so try those first. If this only happened on this assembly, I would delete and pull another out from the catalog if it is stored. Only after I determine that it is a model issue do I properly debug the model.

-

I opened a new scene and it was unable to save as well.

Restarting the computer seems to have fixed the issue, although I will have to recreate the document.

-

1

1

-

-

-

-

Has this issue been fixed, or is it still at large?

-

Disclaimer: Don't get structural advice like this from forums on the internet, professionals will not answer your question as it would be unprofessional and potentially open them up legally if something goes wrong.

Your 50 x 3mm SHS should be strong enough, however, it will largely depend on the structure itself. Where and how you would go about fixing this structure to the walls would very much depend on the structure of the house itself.

If you want to optimize the structure for the space I strongly recommend seeking professional advice so they can properly engineer the structure. You are looking at a structure that is 100-150kg sitting above where people are walking through.

If you want to handyman the job, consider the access ladder may be considered a support if built properly, and definitely consider using ground supports as opposed to fixings into the walls. Also consider how you will fix all the parts of the structure together, and how you will get it from the workshop to the room in question, you wouldn't want to be welding in a bedroom for example.

-

1

1

-

-

If you just want to rotate it, I would suggest using positioning constraints, that would be by far the easiest way I can think of. Lock which ever axis want and then make an edge or vertex coincident on the plane of interest and done.

-

Gigi, what you are trying to do is simple, but how you are doing it may throw you into trouble. If you are using the pull-push handles then where you click is the key issue, the handles will move the part face so that the point you clicked is on the same plane as the face. I encounter this a fair bit, and as I only need to the nearest millimeter accuracy my method is to roughly find the intersection point then zoom in and try to click on the intersection.

This likely isn't the best option, but is relatively fast and flexible.

-

One way to do that expression is mathematically, it looks like you want to round up to the nearest 5mm so:

=(5mm*int(((Hei/5mm) +1)))

-

The way I would set that up is to first decide (hardcode) a maximum distance between blocks, use that (rather the block centres) to determine the number of blocks, then divide the total length by the number of blocks +/- 1 depending on how you want to set the end blocks. So

Num Blocks = Modulus(Length/[max distance]) //Modulus to ensure rounded down integerBlock Centre distance = (Length - Block Width + 6cm)/Num Blocks //This will have the blocks overhanging 3cm each side if centred

I should mention that there are a few details that would need to be changed depending on how you implemented the blocks.

-

My understanding of the matter is that an architect designs the building, what you have done, and a civil/structural engineer signs off on the design saying it meets the criteria of the various codes. However, the specifics of the legislation in New York are certainly beyond my general knowledge, though I doubt the professions are too different in the US.

In short you need a civil engineer, with a structural engineer being the specific specialization of civil engineer.

Here is the first one that popped up in a search: https://www.levelengineering.com/ny/ although I do not know if they use Ironcad.

-

That looks like something one of the devs should look at, but if I were to guess I would say that it expects the denominator to be a scalar so it is converting 1mm to default units then to scalar.

Round off in Parameter Table

in General Discussion

Posted

Kim, you may have to recreate a rounding function. The easiest way would be INT(2 x DEGREE - INT13). Basically the idea is to take the integer of the truncated plus twice the difference of the original and truncated numbers.