-

Posts

2,753 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Downloads

Articles

Gallery

Posts posted by dleczynski

-

-

Import DXF with layers

-

1

1

-

-

New numbering option by cabinet number

-

my mistake. Because I have a resolution of 1920x1040 on movies and it decreased to 1917x1038, that's why it was doing 720. Now the next ones will be 1080p Thanks;)

for example:-

1

1

-

-

Now is 720p probably you not change? I test 1080 is not good for recording screen for me

-

Painting usefull tool

-

One wood grain for display ind drawing

-

Fast change material

-

New base status marker

-

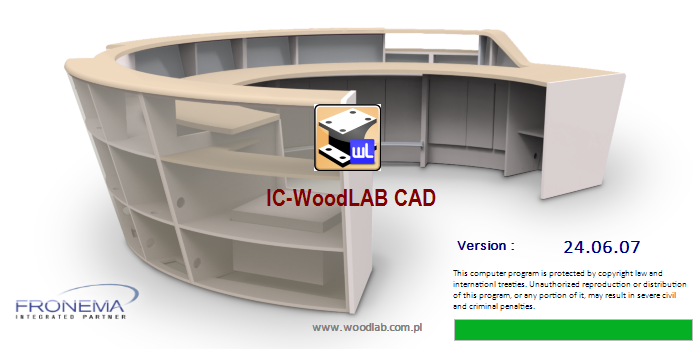

WOODLAB CAD / CAM + Drilling aggregate - X and Y axis drilling optimization -automatic rotation of the forms in the absence of drills in the Y axis -automatic form homing - drilling based on a barcode label - through and non through drilling strategies - laser support for measuring forms - fittings libraries as standard

-

New drawer system BLUM MERIVOBOX

-

60% faster desing 3D

-

-

-

-

Easy design for 5 axis SAW

-

Brand new production system for furniture / fronts / unusual projects v2022. Soon we will insert info on CNC machining management, how it works now, but ...

Earlier this year, we set the goal of "AI" to be applied in design and production. The point here is that the designer selects the type of milling, hardware, material, and the CAM, depending on the further purpose (CNC machines, tools, material, etc.), performs the functions of securing the machine, determines the direction of milling, generates cutouts according to type so that it does not tear off the edges, but at the same time, when we change a given type of material or machine, for example, these cuts change to the outline of the mat, the direction of milling changes (counter-rotating / concurrent), the way of inputs, outputs, calculation of the chord, multi postprocessor that supports 5 machines simultaneously , milling strategies depending on the cutter material, automatic addition of beams and suction cups, 3-5 axis cutting, allowances, optimization of ISO drilling aggregates with support of SERON angle aggregates, laser operation, control of zones and tool departures to reduce travel times, etc. that is, everything that can be mathematically described and programmed / automated.

Feel free to contact me in Krakow

www.woodlab.com.plOur goal for the second part of the year is Is it possible to unify furniture production (integration of 3D projects with pro100, palletecad, topsolid into woodlab cad / cam) and introduce a single furniture production scheme? In the mechanical industry, most people communicate with the ISO DIN PN ANSI standards. In the furniture industry, each company has a different production style, and the goal is the same

-

Nice! web viewer in IRONCAD 2022

-

New customer! Design in IRONCAD and production WOODLAB.

-

A mathematical post-processor speeds up production. See how machining triangles reduce milling time

-

Bad and good method make frontals. Who is better?

-

-

bootcamp wants over 70GB of disk space and I have 128GB so I have no resources. It is not easy to do a bootcamp. IRONCAD from woodlab wants 15GB of resources and has no place to work. not today

-

today i install ironcad on macbook

keep fingers crossed!

keep fingers crossed!

-

here is create by ironcad. if you wan't how i sent priv. I use ICD is better than caxa for this instructions

https://domelmeble.pl/upload/manual/NERO-16.pdf-

1

1

-

woodlab for technological furniture production CNC

in General Discussion

Posted

Big trade DREMA 2022 and IRONCAD+WOODLAB!

https://www.drema.pl/pl